Part 3 — The AI Bottleneck Nobody Is Talking About

CES 2026: The Line Between Science Fiction and Engineering Just Disappeared

Topics: Test, Big Data, Analytics, Viviota, SAP, Sensors, automotive industry, Real-time computing, COTA, U.S. Grand Prix, Autonomous Vehicles, Sensor Data, Machine Learning, aerospace, Analog Data, ADAS, Hybrid Cars, NIWeek, ESS, ANC, Sensor Data Management, data cleansing, simulation, webinar, Smart Factories, Manufacturing, Intelligent Data handling, Software, LabVIEW, Build Back Better Act, Digital transformation

Where Real-World Engineering Data Meets Synthetic Intelligence

Topics: Engineering Data, Big Data, Analytics, automotive industry, Electric Grid, Autonomous Vehicles, Machine Learning, aerospace, Hybrid Cars, Electric Cars, Sensor Data Management, Edge Computing, Factory 4.0, Manufacturing, Intelligent Data handling, Software, Digital transformation

CES 2026: The Line Between Science Fiction and Engineering Just Disappeared

Walking the floor at CES this year felt like stepping into a future that suddenly arrived all at once. Everywhere you turned, there were robots, intelligent machines, autonomous systems, and increasingly lifelike interfaces. But unlike past years, many of these technologies no longer felt like fragile demos or research experiments.

Topics: Engineering Data, Big Data, Analytics, Autonomous Vehicles, Analog Data, Digital transformation

CES 2026 Blog Series: Mind-boggling technology observations

Over the next few weeks, I’ll be sharing a short series of observations from CES 2026 across three themes:

Topics: Engineering Data, Big Data, Analytics, IIoT, Autonomous Vehicles, Sensor Data, Machine Learning, Analog Data, Electric Cars, ANC, Sensor Data Management, Edge Computing, Factory 4.0, Manufacturing, Intelligent Data handling, LabVIEW, Digital transformation

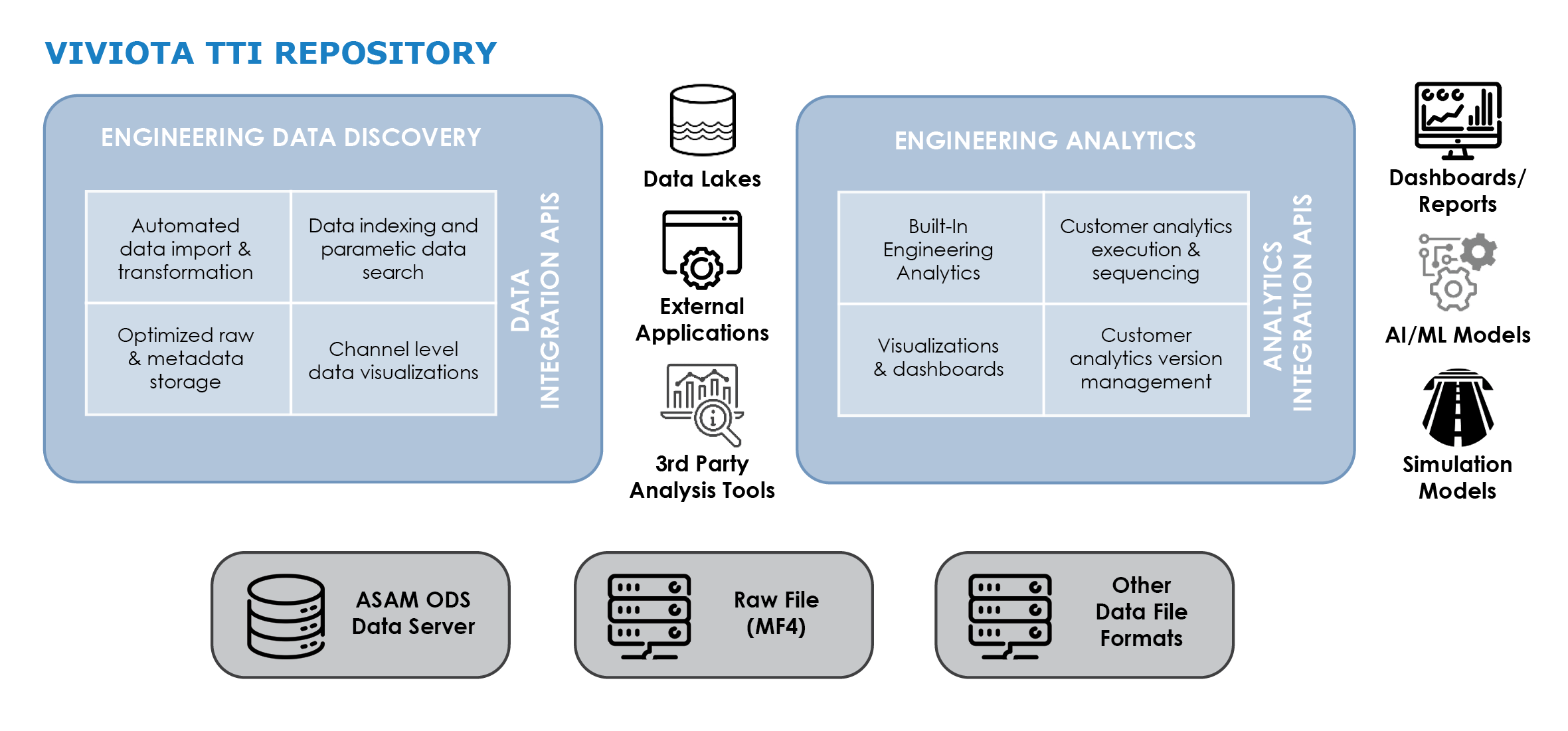

Stop Losing Time: How Engineering Data Can Save Millions

Engineering teams possess an underutilized goldmine in today’s fast-paced industrial landscape: their data. From sensor readings and vibration logs to video, sound, and test metadata, engineering data holds critical insights that can accelerate innovation, reduce costs, and safeguard operations against failure. Yet, a significant portion of engineering time is wasted merely searching for, organizing and wrangling data to make it usable.

Topics: Engineering Data, Big Data, Analytics, Viviota, IIoT, automotive industry, Autonomous Vehicles, Sensor Data, Machine Learning, aerospace, Analog Data, Sensor Data Management, data cleansing, simulation, Edge Computing, Manufacturing, Intelligent Data handling, Build Back Better Act, EV, Digital transformation

NVIDIA Show Report: AI & ML Take Center Stage at the "Woodstock of AI"

Topics: Engineering Data, Big Data, automotive industry, Autonomous Vehicles, Machine Learning, Analog Data, data cleansing, Edge Computing, Intelligent Data handling, Digital transformation

The 5 Things Engineering Teams Should Be Doing Right Now to Utilize AI & ML Technologies

Listen to our blog:

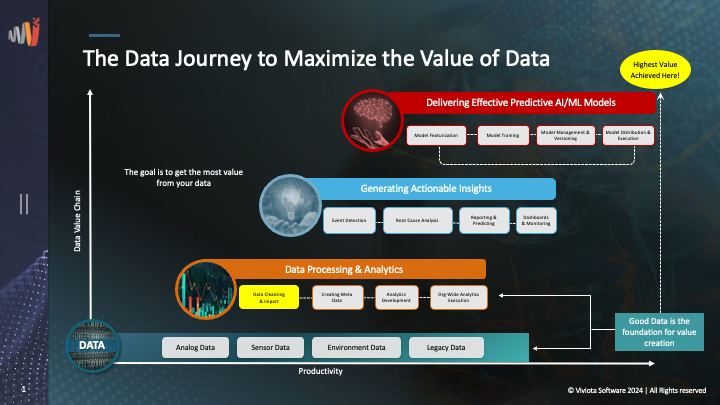

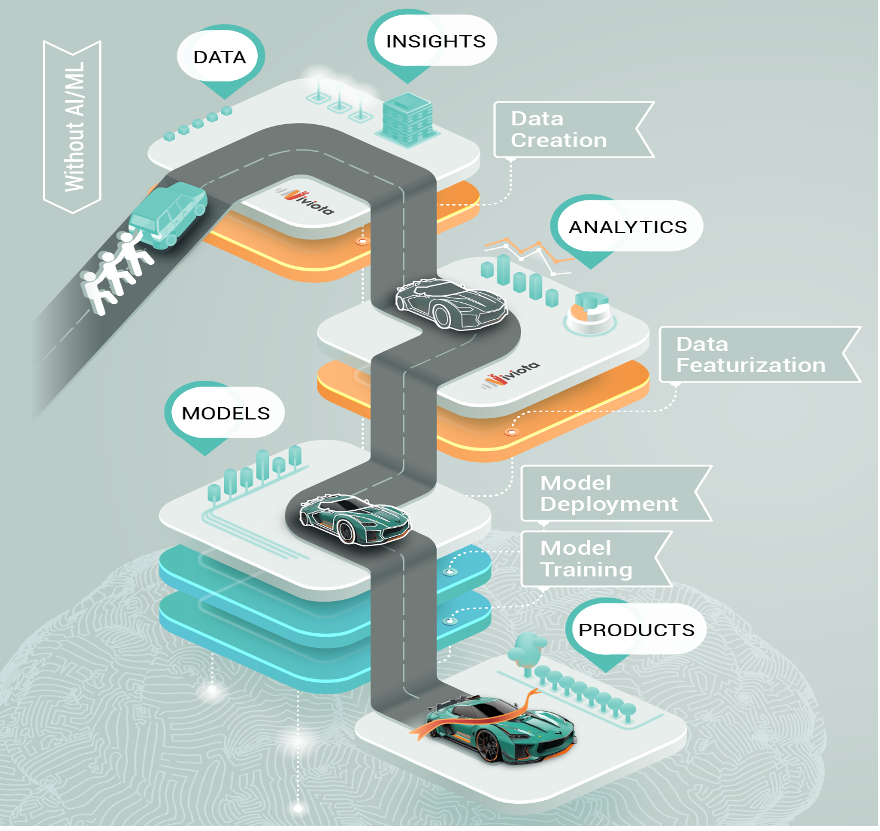

According to a recent survey, 47% of companies today consider AI/ML as a top priority in 2024. Yet, according to Harvard Business Review “cross-industry studies show, on average, less than half of an organization's structured data is actively used in making decisions—and less than 1% of its unstructured data is analyzed or even used at all.” 1

This statistic should concern R&D or Engineering decision-makers. Companies are drowning in data, and very few companies can leverage their data because they are stuck trying to find, access, and connect various data sources. So first ask yourself these three questions:

Topics: Analytics, simulation, Intelligent Data handling, Digital transformation

Accelerating AI & ML Analysis with TTI’s Data Cleansing Technology

The importance of data preparation has grown exponentially with the rise of AI. Data comes in many forms and formats, including homegrown applications, SQL databases, files, sensors, video, and physics-driven analog data. Traditionally, data cleansing is defined as detecting and correcting (or removing) corrupt or inaccurate records from a dataset, table, or database. The data challenge presented is identifying the data's incomplete, incorrect, inaccurate, or irrelevant parts and then replacing, modifying, or deleting the dirty or coarse data.

Topics: Sensor Data, Sensor Data Management, data cleansing

Reducing Technical debt and increasing the Value of Data

Please make sure to sign up for this exclusive summit in Novi, MI!

Since our company's inception, we have had the privilege of engaging with a diverse range of customers, all grappling with a common challenge-the management of their data. Whether a small business or a large enterprise, the issue of technical debt, a result of short-term thinking about data, is a consistent theme. Technical debt, in this context, refers to the cost that accumulates when short-term solutions are implemented to address immediate needs, leading to a complex, inefficient, and duplicate data infrastructure over time.

This technical debt spawns from a patchwork of applying technologies one by one, reacting to a current need. A prime example is when companies opt for a do-it-yourself plan because they don't have to engage procurement or IT and currently have resources available. Aside from the expanding technical debt, this strategy ignores the ongoing service support issues that cost 10x what an off-the-shelf product when looking at the total cost of ownership. I have observed extreme examples of this behavior at companies that have been around for many years. The decision to patch things and solve a short-term pain is very tempting. Leaders convince themselves they can do it cheaper and better because it is custom-built for them versus the pain of trying to convince stakeholders to procure a product.

It's clear that addressing and reducing technical debt is not a simple task. It requires a structured methodology for identifying, justifying, and funding new projects. This funding is not just about acquiring technology; it's about generating the emotional momentum needed to overcome the inertia that has built up over many years in replacing outdated technology.

Topics: Sensor Data, Sensor Data Management, data cleansing

The 5 Things Engineering Teams Should Be Doing Right Now to Utilize AI & ML Technologies

According to a recent survey, 47% of companies today consider AI/ML as a top priority in 2024. Yet, according to Harvard Business Review “cross-industry studies show, on average, less than half of an organization's structured data is actively used in making decisions—and less than 1% of its unstructured data is analyzed or even used at all.” 1

This statistic should concern R&D or Engineering decision-makers. Companies are drowning in data, and very few companies can leverage their data because they are stuck trying to find, access, and connect various data sources. So first ask yourself these three questions:

Topics: Analytics, simulation, Intelligent Data handling, Digital transformation